| Authors | Tofel, P., Majzner, J., Sedlák, P., Cséfalvay, G. |

| Date | 2012-11-20 |

| Funding | MPO TIP FR-TI2/536 Research and development progressive instruments for innovation surface quality of cast billets, bars and wires |

| Responsible | prof. Ing. Radimír VRBA, CSc. |

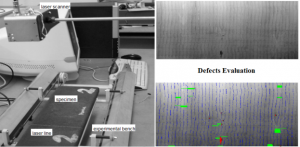

The all system consists of precise laser scanner for high speed profile acquisition, optical detector of motion and computer. The laser scanner (SCANCONTROL 2750-100 made by Micro-Epsilon Company) is based on laser triangulation principle for two-dimensional profile detection on different target surfaces. By using special lenses, a laser beam is enlarged to form a static laser line and is projected onto the target surface. A high quality optical system projects the diffusely reflected light of this laser line onto a highly sensitive sensor matrix. We get information about distance (z-axis) and position along the laser line (x-axis) also. The integrated FireWire interface enables both complete controls for several scanCONTROL systems via a computer, as well as high data rates. In the case of moving objects, it is possible to obtain 3D surface measurement. Optical detector of motion measure speed object displacement under the laser scanner in velocity range 0 to 2 m/s. Computer is used for reconstruction and evaluating 3D surface from information about moving object and 3D data acquired from laser scanner. In this case are possible found defects and other anomaly on object surface with high precision.